We Are BMR (Battery Manufacturing & Recycling) Of Bharat India.

Search for anything.

Products

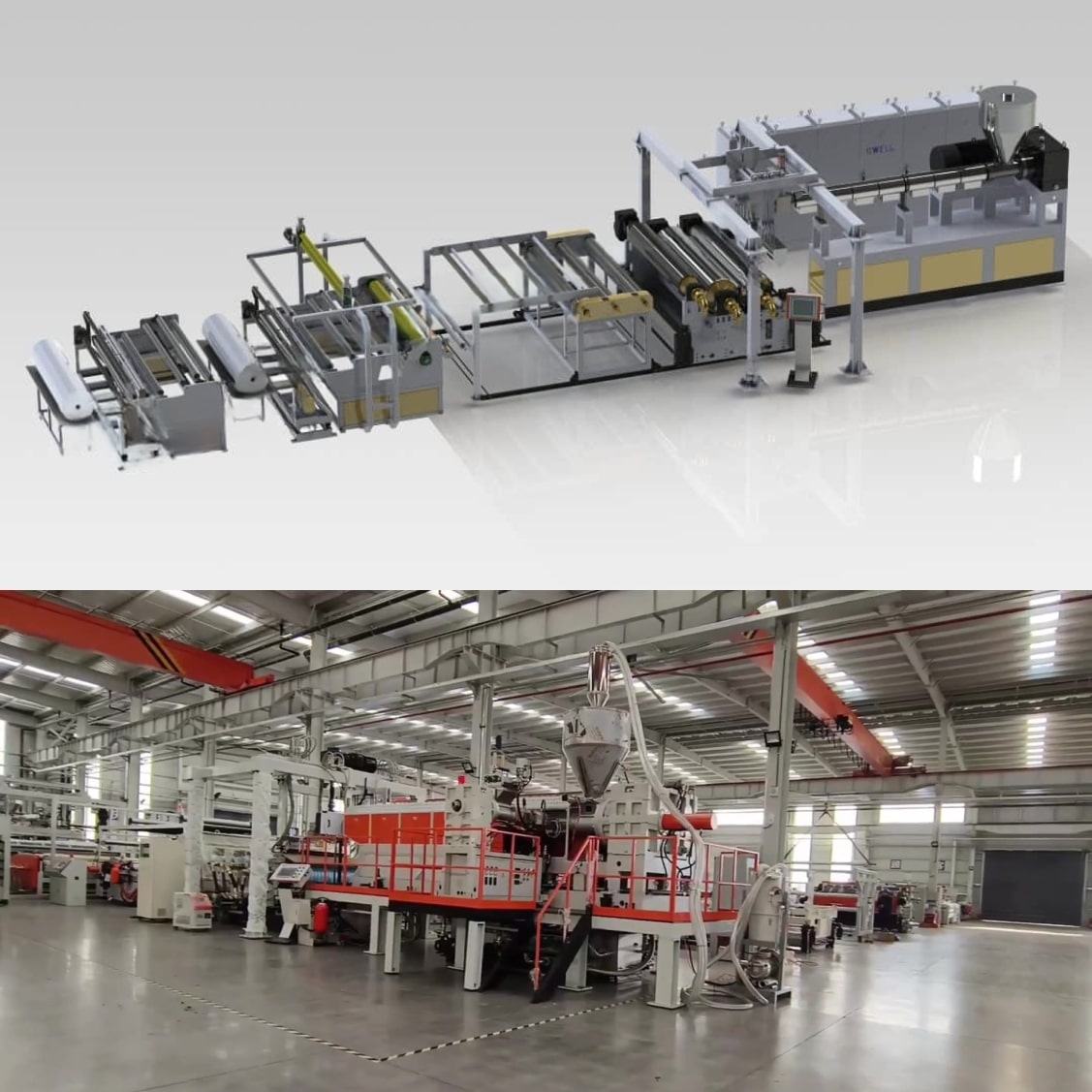

Lithium-ion Battery Recycling Machine Workflow

Our company's waste lithium-ion battery recycling machine processes materials step-by-step using shredders, crushers, and grinders, followed by separation through air separation facilities. The entire equipment system operates under a closed negative pressure to minimize dust pollution and includes pulse dust collection facilities to gather dust generated during separation and subsequent processes.

Shredder: Shreds lithium batteries into smaller

pieces.

Shredder: Shreds lithium batteries into smaller

pieces.

Hammer Crusher: Performs secondary crushing of the

shredded materials.

Hammer Crusher: Performs secondary crushing of the

shredded materials.

Grinder: Grinds the crushed materials.

Grinder: Grinds the crushed materials.

Separation Machine: Separates the materials after

grinding.

Separation Machine: Separates the materials after

grinding.

Collector: Collects and releases dust.

Collector: Collects and releases dust.

Pulse Purifier (Air Cleaner): Cleans all dust

produced during the operation of the entire system.

Pulse Purifier (Air Cleaner): Cleans all dust

produced during the operation of the entire system.

Classifying Screen: Screens materials sorted by the

separation machine, filtering out larger metal

materials.

Classifying Screen: Screens materials sorted by the

separation machine, filtering out larger metal

materials.

Magnetic Machine: Separates nickel from other metals.

Magnetic Machine: Separates nickel from other metals.

Gravity Separator: Separates finer materials

obtained from the screening machine, ensuring

complete metal separation.

Gravity Separator: Separates finer materials

obtained from the screening machine, ensuring

complete metal separation.

High-pressure Blower: Maintains the entire system in

a negative pressure state to collect materials

and purify the air.

High-pressure Blower: Maintains the entire system in

a negative pressure state to collect materials

and purify the air.

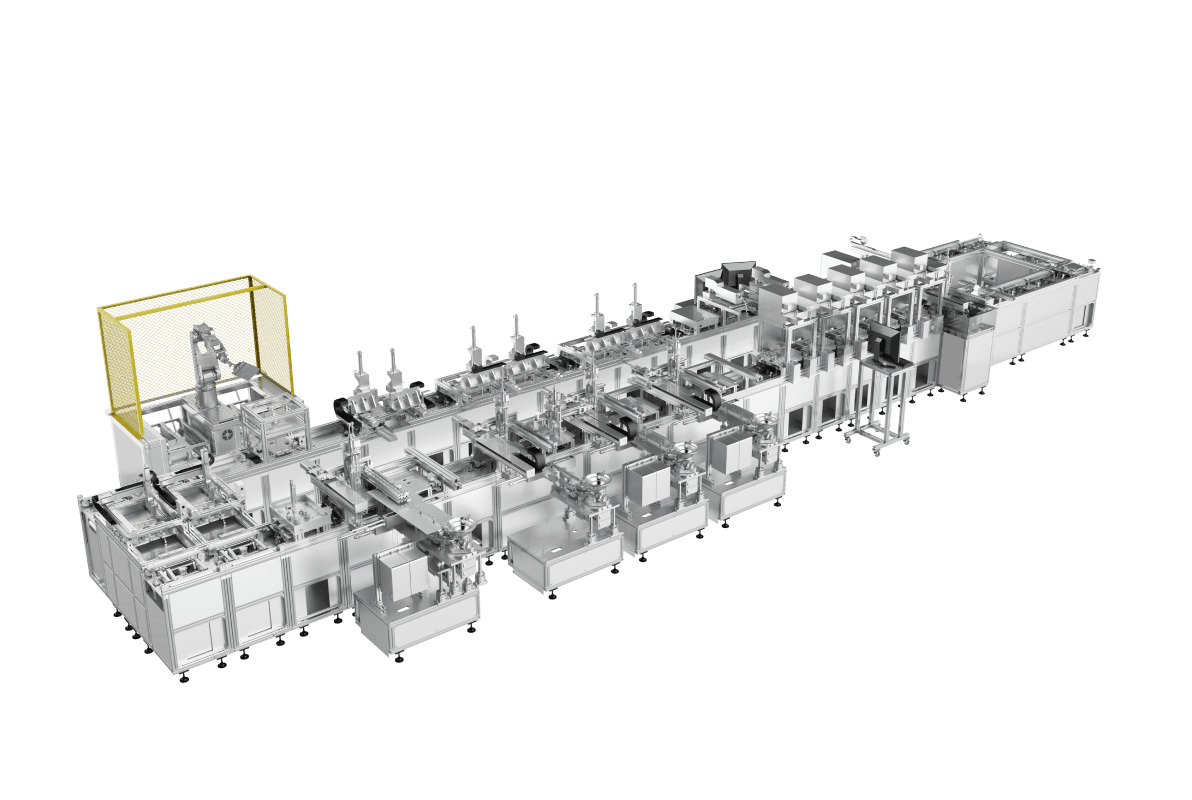

Empowering Your Production Line with Customized, Smart Solutions

Operation & Automation Advantages

High automation and multi-product compatibility.

High automation and multi-product compatibility.

Set up reasonable inventory to reduce the risk of line

stoppage due to equipment failure, lack of

materials, abnormal shipments, etc.

Set up reasonable inventory to reduce the risk of line

stoppage due to equipment failure, lack of

materials, abnormal shipments, etc.

Reduce labor force, improve space utilization, and reduce

costs while increasing efficiency.

Reduce labor force, improve space utilization, and reduce

costs while increasing efficiency.

Go through the entire line of material operation to reduce

the risk of multi-manufacturer docking.

Go through the entire line of material operation to reduce

the risk of multi-manufacturer docking.

Smart Factory Application Scenarios

Procurement Collaboration: Rapid response, precise

delivery, and efficient collaboration through

online interaction.

Procurement Collaboration: Rapid response, precise

delivery, and efficient collaboration through

online interaction.

Production Plan: Graphical flexible scheduling, transparent

production progress, real-time

production report push, easy to analyze and predict material requirements.

Production Plan: Graphical flexible scheduling, transparent

production progress, real-time

production report push, easy to analyze and predict material requirements.

Warehousing and Logistics: Standardize warehousing

operation processes, increase transparency

of warehouse management, and realize a push-pull material management mode for

production.

Warehousing and Logistics: Standardize warehousing

operation processes, increase transparency

of warehouse management, and realize a push-pull material management mode for

production.

Product Process: R&D and production are precisely matched,

product information is visible online,

and the production process is coordinated and matched.

Product Process: R&D and production are precisely matched,

product information is visible online,

and the production process is coordinated and matched.